Product | TAC System Formwork vs Conventional Technology

Traditionally, timber and plywood are used for formwork fabrication for the construction of concrete structures. However, it needs many skilled and unskilled workers besides being very time consuming. In today’s competitive market, speed and efficiency is of primary importance.

When TAC System Formwork was firstly introduced into the market of Malaysia in the late-1990s, our aluminium formwork system achieves rapid market acceptance from the local and overseas construction industry. It is proven to be successful in the construction of mass housing projects both low-rise and high-rise buildings around the world.

Among the key success factors of this system are:-

Speed of Construction

Fast construction is assured and the system is suitable for larger magnitude construction of repetitive nature at one project site. Our aluminium formwork system allows 100% of the building superstructure to be constructed or formed at the rate of 6 days per floor, as a result of saving 10 to 15 days per floor in the overall completion period using the traditional formwork system approach.

Quality of Work

Using TAC System Formwork, all the elements of the building has exceptionally good quality with accurate dimensions for the openings and the right angles at meeting points. The flat, off-the-form finish can eliminate the need for additional plastering. Concrete surface requires a 5mm skim coat are good to receive paint. Services can be accurately located and cast-in as the slab concrete is being poured, leaks are eliminated.

Comprehensive Workplace Safety

The system provides an inherent safety features in the use of props which need not be removed to release the slab forms. Overlooking of re-propping in one of the commonest causes of fatal accidents on building sites.

Independence from Scarcity of Skilled Tradesmen

TAC System Formwork eliminates the need of skilled plasterers, carpenters, and bricklayers. The system is able to reduce construction time and cost significantly because it has eliminated demand for skilled jobs.

Scaffolding

TAC System Formwork provides safety work platform brackets which ascend the building as it being constructed without the need of scaffolding. There is an added advantage that the infrastructure can proceed in parallel with the building construction and the contractor has unimpeded access to the base of the building.

Cranage

The crane is not required for the movement of the forms up the building as the construction proceeds. Thus, the crane is available for concrete and steel placing and other materials movement. The crane is only required for moving the forms down from the top of the completed building.

Structure

TAC System Formwork allows consideration of a “load bearing walls” structural design approach. A LBW design is structurally efficient and cost effective as compared to the traditional “reinforced concrete frame” approach. Our aluminium formwork system is modular and it can be fitted to any architectural or structural layout.

Reliability

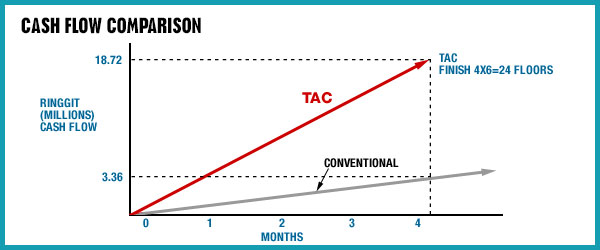

TAC System Formwork gives a remarkable construction speed and speed reliably. We will contractually undertake to complete 4 floors per month (i.e. 4 floors at 6 days per floor, plus days to spare for items outside control e.g. crane breakdown, access problems, access for ready mix trucks, etc.) and would be confident of exceeding that rate.

Overall Financial Advantage

When all of the above are taken into consideration over the construction period of a suitable project (i.e. one where there are more than about 50 repeats of a typical layout), the overall profit to the Developer can be increased by a factor of from 10 to 30%. The overall advantage is the cost and time savings to the developer.

TAC System Formwork has a very competitive state-of-the-art technology which has gained market acceptance over a relatively short period of time as evidenced from the major projects completed and new projects secured to-date. The fact that our company has made inroads in the highly competitive and advanced countries such as Taiwan and Hong Kong within such a relatively short time is sufficient of TAC’s superior formwork technology.

With the revival in the local construction industry, in particular that of low and low-medium cost houses, as well as massive demand for speedy social housing development in the countries in the Asian region and other parts of the world, TAC System Formwork foresees a tremendous growth potential in its business over the medium term. Our strategy of market penetration to overseas will also mitigate any possible major downturn in the local construction industry.